OceanGuard® BWMS

OceanGuard® BWMS is developed by Headway Technology Co., Ltd. together with leading universities in China.

OceanGuard® Filter Specification

Type | Volume(L) | Dimension (MM) | Flow Range(M3/H) |

HMT-50F | 60 | 540*510*1450 | 10-50 |

HMT-100F | 120 | 650*565*1445 | 10-150 |

HMT-200F | 205 | 800*670*1600 | 10-250 |

HMT-300F | 300 | 900*780*1705 | 50-400 |

HMT-500F | 450 | 980*780*1705 | 50-550 |

HMT-600F | 650 | 1060*895*2330 | 50-700 |

HMT-800F | 860 | 1180*1015*2380 | 50-900 |

HMT-1000F | 1100 | 1300*1115*2530 | 50-1100 |

HMT-1500F | 1490 | 1440*1230*2610 | 100-1600 |

HMT-2000F | 1900 | 1500*1230*3260 | 100-2100 |

HMT-3000F | 2500 | 1700*1455*3480 | 100-3100 |

HMT-4000F | 4000 | 1900*1675*3600 | 100-4500 |

HMT-5000F | 5900 | 2100*1915*4050 | 100-5500 |

S-ZF1-V | 170 | 760*655*1679 | 10-150 |

S-ZF2-V | 190 | 760*655*1679 | 10-250 |

S-ZF3-V | 280 | 800*790*1880 | 50-400 |

S-ZF4-V | 330 | 930*830*2050 | 50-550 |

S-ZF5-V | 400 | 920*805*2200 | 50-700 |

S-ZF6-V | 800 | 970*960*2700 | 50-900 |

S-ZF7-V | 1250 | 1255*1190*2700 | 50-1100 |

S-ZF8-V | 1375 | 1255*1190*2633 | 50-1300 |

S-ZF9-V | 1800 | 1550*1500*2800 | 100-1600 |

S-ZF10-V | 2400 | 1560*1520*3110 | 100-2200 |

S-ZF11-V | 2500 | 1560*1520*3250 | 100-2500 |

S-ZF12-V | 4200 | 1800*1700*3756 | 100-3500 |

S-ZF13-V | 5400 | 1850*1750*4150 | 100-4500 |

S-ZF1-H | 170 | 1599*655*760 | 10-150 |

S-ZF2-H | 190 | 1599*655*760 | 10-250 |

S-ZF3-H | 280 | 1800*765*980 | 50-400 |

S-ZF4-H | 330 | 2030*795*1025 | 50-550 |

S-ZF5-H | 400 | 2145*795*1025 | 50-900 |

S-ZF6-H | 800 | 2600*970*1210 | 50-900 |

S-ZF7-H | 1250 | 2700*1190*1427 | 50-1100 |

S-ZF8-H | 1375 | 2533*1190*1427 | 50-1300 |

S-ZF9-H | 1800 | 2700*1350*1600 | 100-1600 |

S-ZF10-H | 2400 | 3100*1520*1645 | 100-2200 |

S-ZF11-H | 2500 | 3100*1520*1645 | 100-2500 |

S-ZF12-H | 4200 | 3756*1700*1800 | 100-3500 |

S-ZF13-H | 5400 | 3970*1740*1920 | 100-4500 |

OceanGuard® EUT Specification

Type | Power(KW) | Dimension(mm) | Capacity Range(m³/h) |

HMT-50E | 0.8 | 426*411*1041 | 10-85 |

HMT-100E | 1.5 | 426*555*1041 | 10-150 |

HMT-200E | 3 | 426*555*1376 | 10-250 |

HMT-300E | 4.5 | 426*555*1701 | 50-350 |

HMT-450E | 6.8 | 456*601*1821 | 50-500 |

HMT-600E | 9 | 505*631*1957 | 50-700 |

HMT-800E | 13 | 505*781*1957 | 50-900 |

HMT-1000E | 17 | 605*676*2123 | 100-1100 |

HMT-1200E | 21 | 605*786*2123 | 100-1400 |

HMT-1500E | 25 | 665*786*2208 | 100-1700 |

HMT-2000E | 34 | 665*926*2208 | 100-2200 |

HMT-2500E | 42 | 695*1054*2212 | 100-2700 |

HMT-3000E | 52 | 695*1054*2222 | 100-3500 |

HMT-4000E | 69 | 695*1054*2222 | 100-4500 |

Test Report for Corrosion Contrast Experiment for Water Treated by EUT Unit of OceanGuardTM BWMS to Different Materials and Coatings.

Based on the long-term testing , the effects of two test waters on Q235 steel, SS304 and coating materials are the same, indicating that the treated seawater will not change the corrosion rules in the natural seawater for the materials above; and for butyl rubber, the effects of treated seawater on its properties are less than that of natural seawater.

1.Photo of appearance feature of the no-scribe coating specimen immersed in two test waters for 180 days.

|

|

2. Figure 14 Photo of the appearance feature of the scribe-to-primer coating immersed in two test waters for 180 days.

|

|

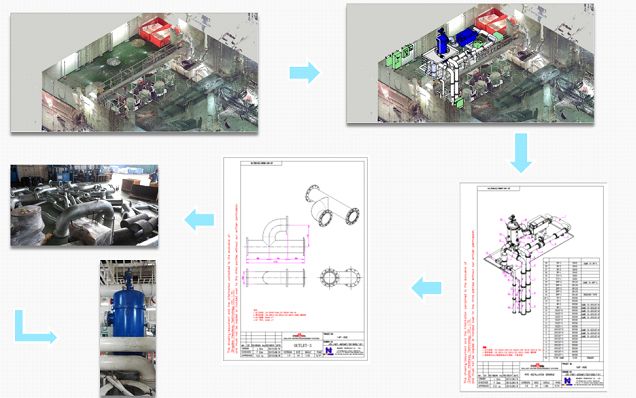

Retrofitting

※Suitable for vessels of all types ※Simple structure and flexible installation ※Small footprint and low power consumption ※One-stop service

Cases

Vessel Type | Installation Time | BWTS | Class |

Cruise Vessel | 2012 | HMT-200 | RINA |

Vessel Type | Installation Time | BWTS | Class |

Tanker | 2014 | HMT-2000Exx2 + HMT-300 | CCS |

Vessel Type | Installation Time | BWTS | Class |

Bulk Carrier | 2015 | HMT-1000x2 | DNV |

Shipping moves over 80% of the world's commodities and transfers approximately 3 to 5 billion tonnes of ballast water internationally each year.

Ballast water is absolutely essential to the safe and efficient operation of modern shipping, providing balance and stability to un-laden ships. However, it may also pose serious threats to ecology, economy and health.

There are thousands of marine species that may be carried in ships' ballast water,

basically anything that is small enough to pass through a ship's ballast water intake

ports and pumps. If these organisms survive transport to other parts of the globe, their impact can be devastating. Such invasions can jeopardize the local ecosystem, and even pose threats to human health. Usually, their effects are irreversible.

The introduction of invasive marine species into new environments by ships' ballast water, attached to ships' hulls and via other vectors has been identified as one of the four greatest threats to the world's oceans. In 2004, IMO adopted the International Convention for the Control and Management of Ships' Ballast Water and Sediments, which will phase in requirements for ballast water treatment over the coming years.

The IMO Regulations

IMO regulations will not affect all ships in the same way. Ballast water treatment will be phased in, with requirements for different ships arriving at different times.

| Keel laid | BW(M3) | Timeline to reach the D-2 Regulation |

Before 2009 | 1,500≤V≤5,000 | 2015 |

| V<1,500 or V>5,000 | 2017 | |

| 2009-2011 | V<5,000 | Dilivery of Vessel |

| V≥5,000 | 2017 | |

After 2012 | All Vessels | Dilivery of Vessel |

| Vessels built in 2009 should be in compliance with the D-2 Regulation by second annual survey,no later than 2011 (A.1005 (25)). Requirements for vessels built in 2010 will be discussed in MEPC 59. | ||

D-2 Regulation |

In International Convention for the Control and Management of Ships' Ballast Water and Sediments, the following D-2 Regulation is addressed regarding management of ballast water.

Data from Landbased testings of OceanGuard® BWMS carried out in NIVA in Sep., 2009.

Test Project | Organism | Unit | Influent water | In treated water on day 0 | In treated water on day 5 | IMO Regulation | Requirement of Califomia |

Land-based Testing | >50μm | Ind./m³ | 213304 | 0 | 0 | <10 | 0 |

>10-50μm | Ind./l | 2.023×106 | 0 | 0 | <104 | <10 | |

E-coli bacteria | cfu/100ml | 2200 | <1 | <1 | <250 | <126 | |

Entrococcus | cfu/100ml | 91 | <1 | <1 | <100 | <33 |

Shipboard testings carried out in MV YOKOHAMA in Nov., 2009.

Test Project | Organism | Unit | Influent water | In treated water on day 0 | In treated water on day 5 | IMO Regulation | Requirement of Califomia |

Ship- board Testing | >50μm | Ind./m³ | 3214 | 0 | 0 | <10 | 0 |

>10-50μm | Ind./l | 3.22×105 | 5.7 | 0.7 | <104 | <10 | |

E-coli bacteria | cfu/100ml | 230 | <1 | <1 | <250 | <126 | |

Entrococcus | cfu/100ml | 42.3 | <1 | <1 | <100 | <33 |