- INTRODUCTION

- SOLUTIONS

- REFERENCE

- Online Inquiry

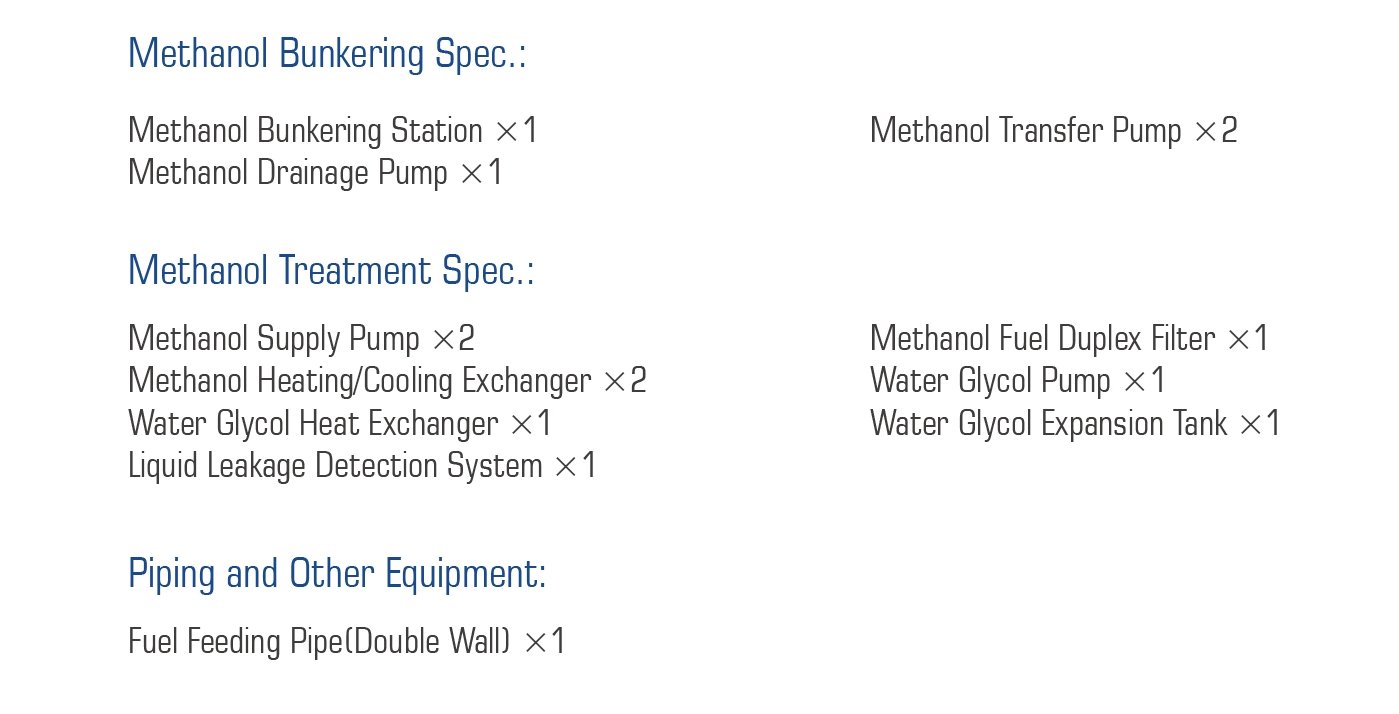

The shipping industry is likely to be driven towards decarbonisation by the twin pressures of customer demand and regulation. Methanol has drawn much attention as a marine fuel due to its potential in GHG emission reduction, ease of handiling, operational safety and engine compatibility.

Methanol burns with only water and carbon dioxide as by-products when combustion is complete. Methanol is an oxygen-rich fuel that combusts in an ICE (Internal Combustion Engine) emitting no sulphur oxides (SOx), a negligible amount of particulate matter (PM) and nitrogen oxides (NOx).

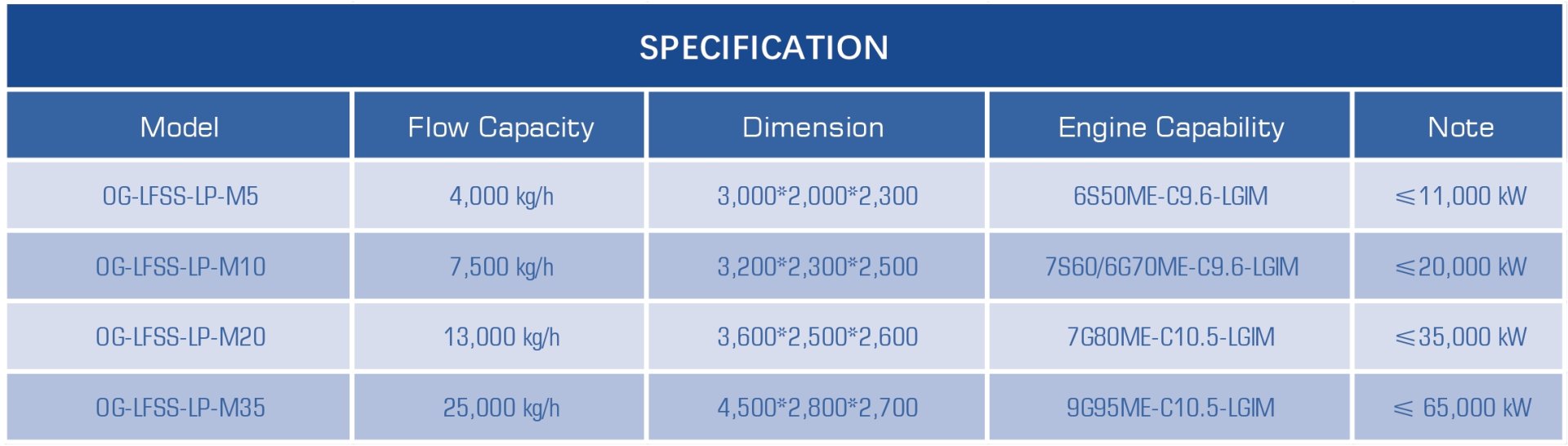

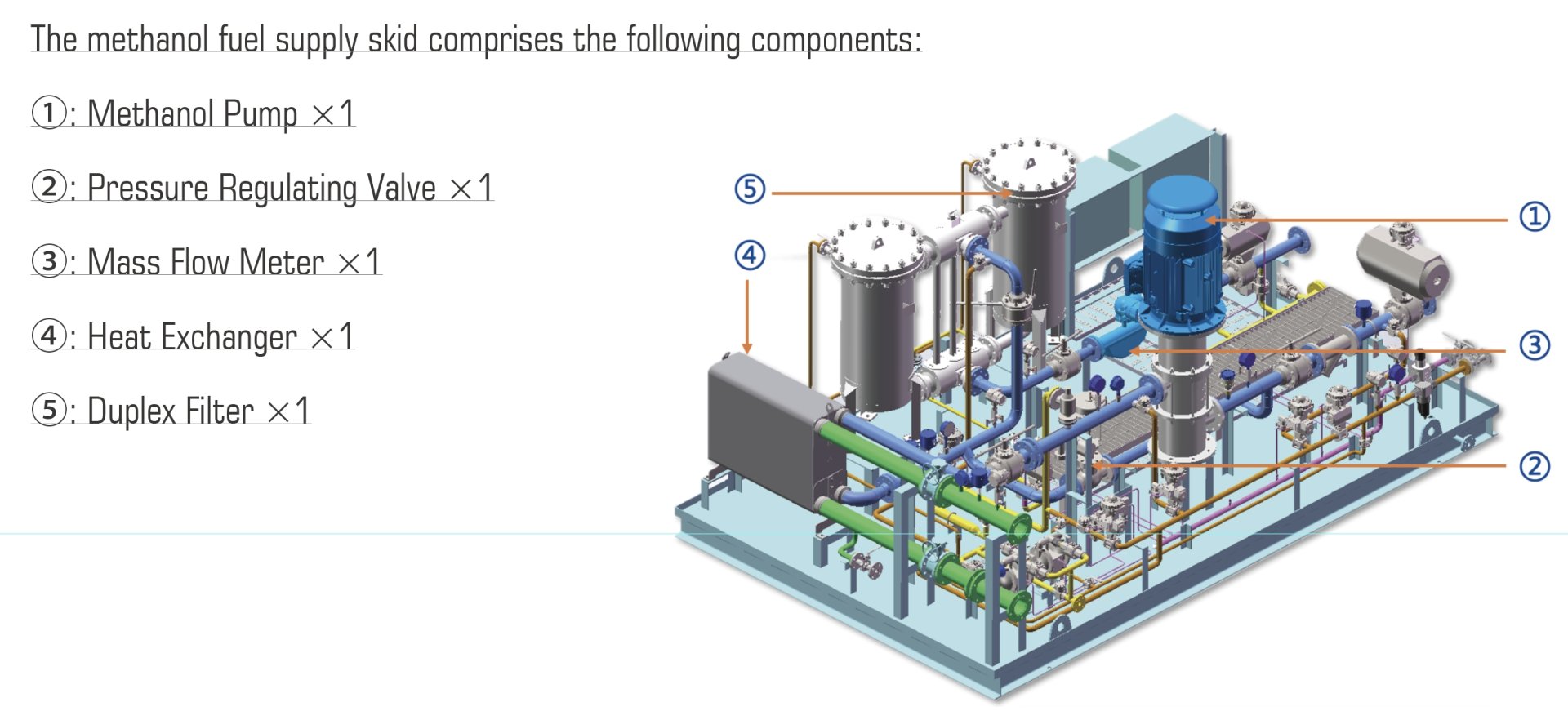

OceanGuard® Methanol Fuel Supply System(LFSS)adopts an optimized and upgraded single-pump supply scheme, featuring a flexible layout, space-saving design, easy maintenance and a low risk of failure.

STABILITY

Adopting magnetic drive fuel supply pumps eliminates the risk of fuel leakage.

REDUNDANCY

Empowered by redundancy design, the system can be maintained without stopping the LFSS.

INDEPENDENT CORE COMPONENTS

Key components including Duplex Filter, Heat Exchanger, Control Cabinet are independently sourced and offer independent after-sales and technical support.

SAFETY PLC

Enhanced by safety PLCs in the Control Unit, provides a real-time self-checking function and one-key operation.

COMPACT DESIGN

Adopting spiral heat exchangers into the system brings a more compact design and less weight.

REMOTE TECHNICAL SUPPORT

The system facilitates remote troubleshooting.

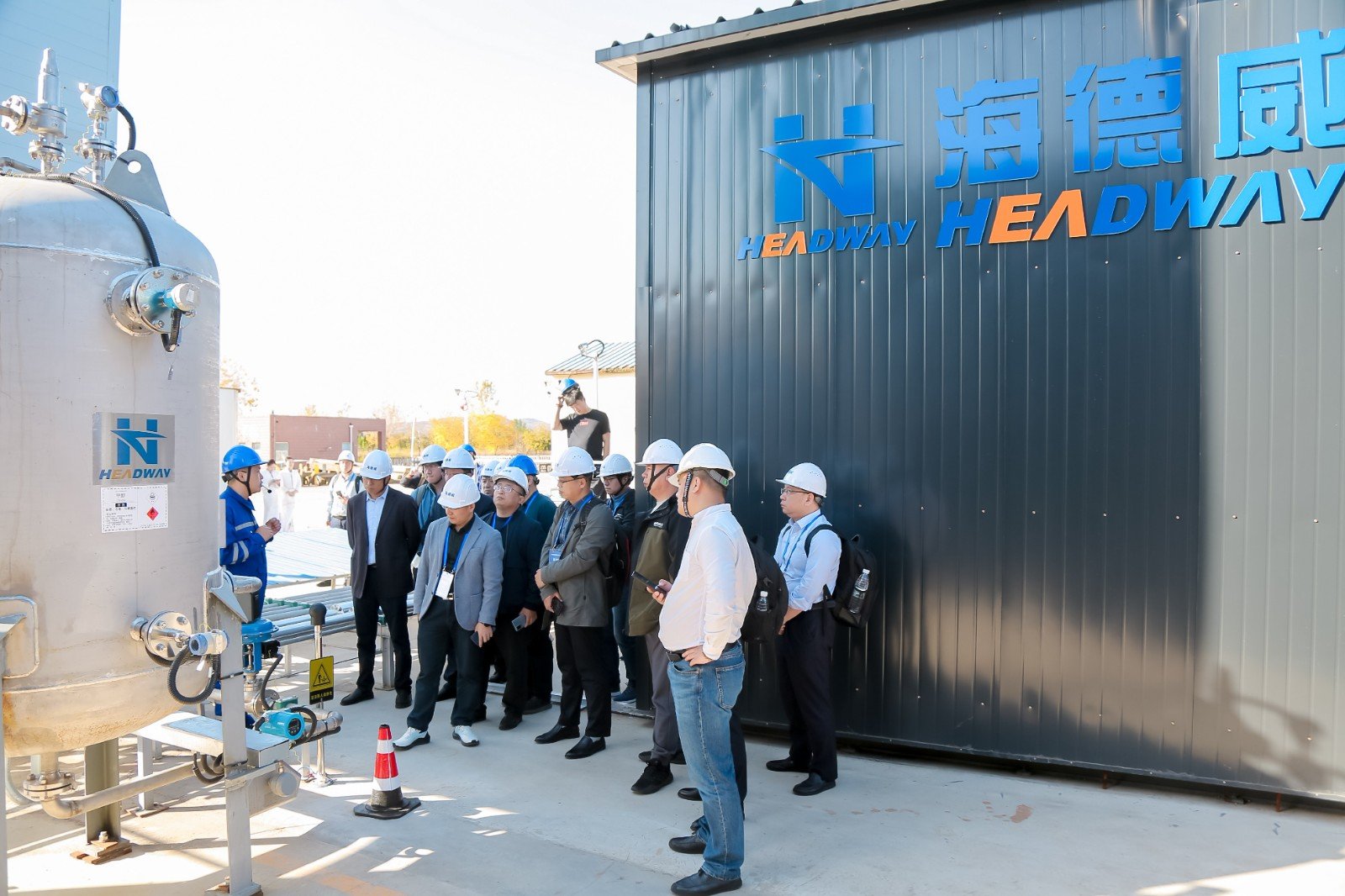

Headway established a dedicated Alternative Fuel Test Center with a USD 2.8 million investment. This facility supports key activities such as technological advancements, performance optimization, product testing, and personnel training for the application of alternative marine fuels like LNG, methanol, and ammonia. Headway has successfully completed LFSS testing for low-speed and medium-speed engines, accumulating over 1,600 hours of operation. The test data has been instrumental in optimizing the LFSS design.

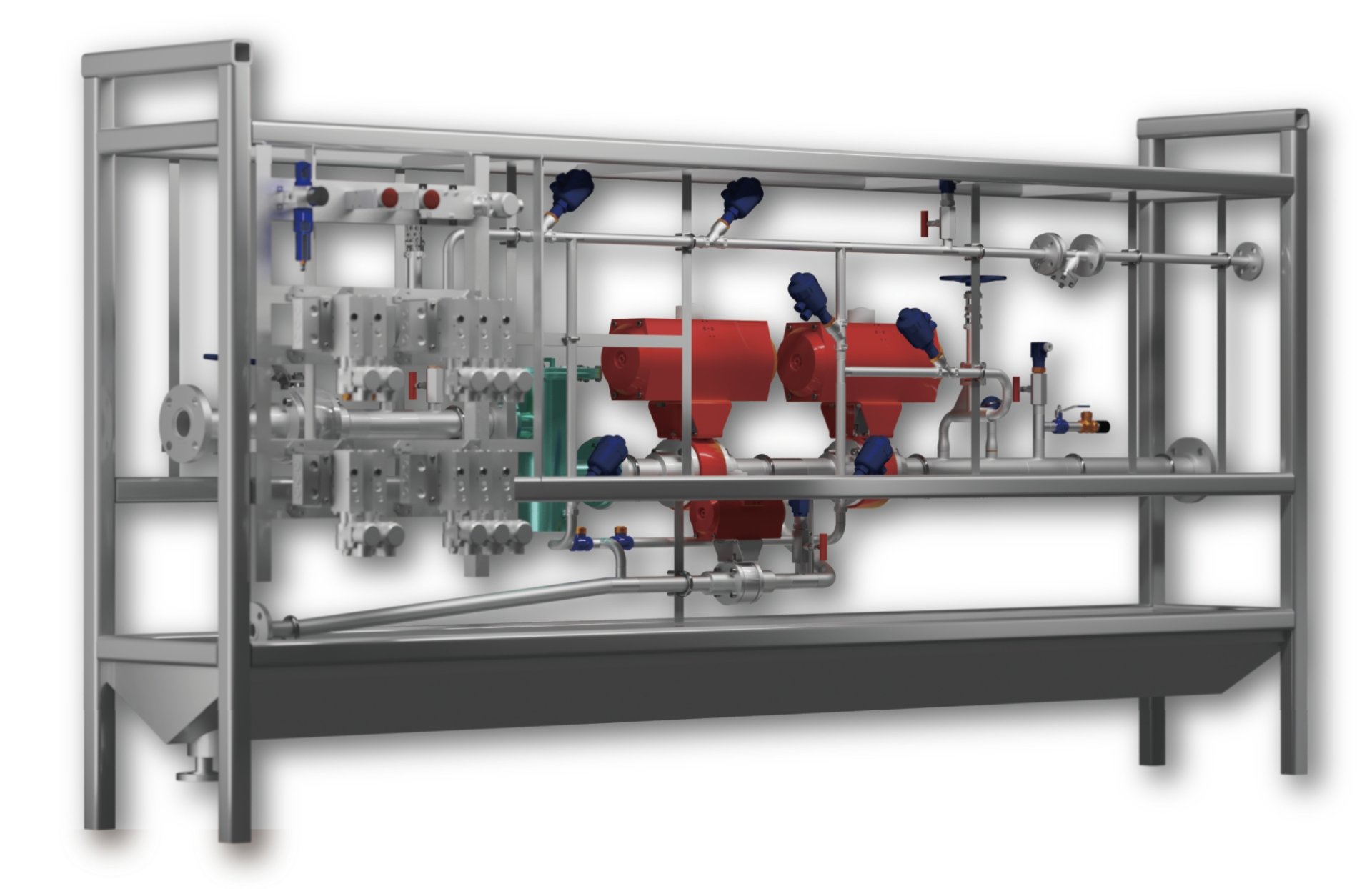

The Fuel Valve Train (FVT) is compatible with Dual Fuel Low-Speed Marine Engines. The Headway FVT is capable of real-time communication with the main engine and quickly adjusts the valve to supply and cut off the fuel supply based on the working condition. With the advantages of compact design and easy maintenance, the FVT can be deployed according to the condition onboard while ensuring complete purge effects.

The Nitrogen Generator can generate required volume of nitrogen at rated purity to be used in fuel supply pipelines. With the permeation process, water, oxygen and some of the argon exit through the membrane sides of the fibers. Only nitrogen will remain as product. The Nitrogen Generator can meet the nitrogen requirement of most vessels with low power consumption, small size and high purity (no less than 99.5%).

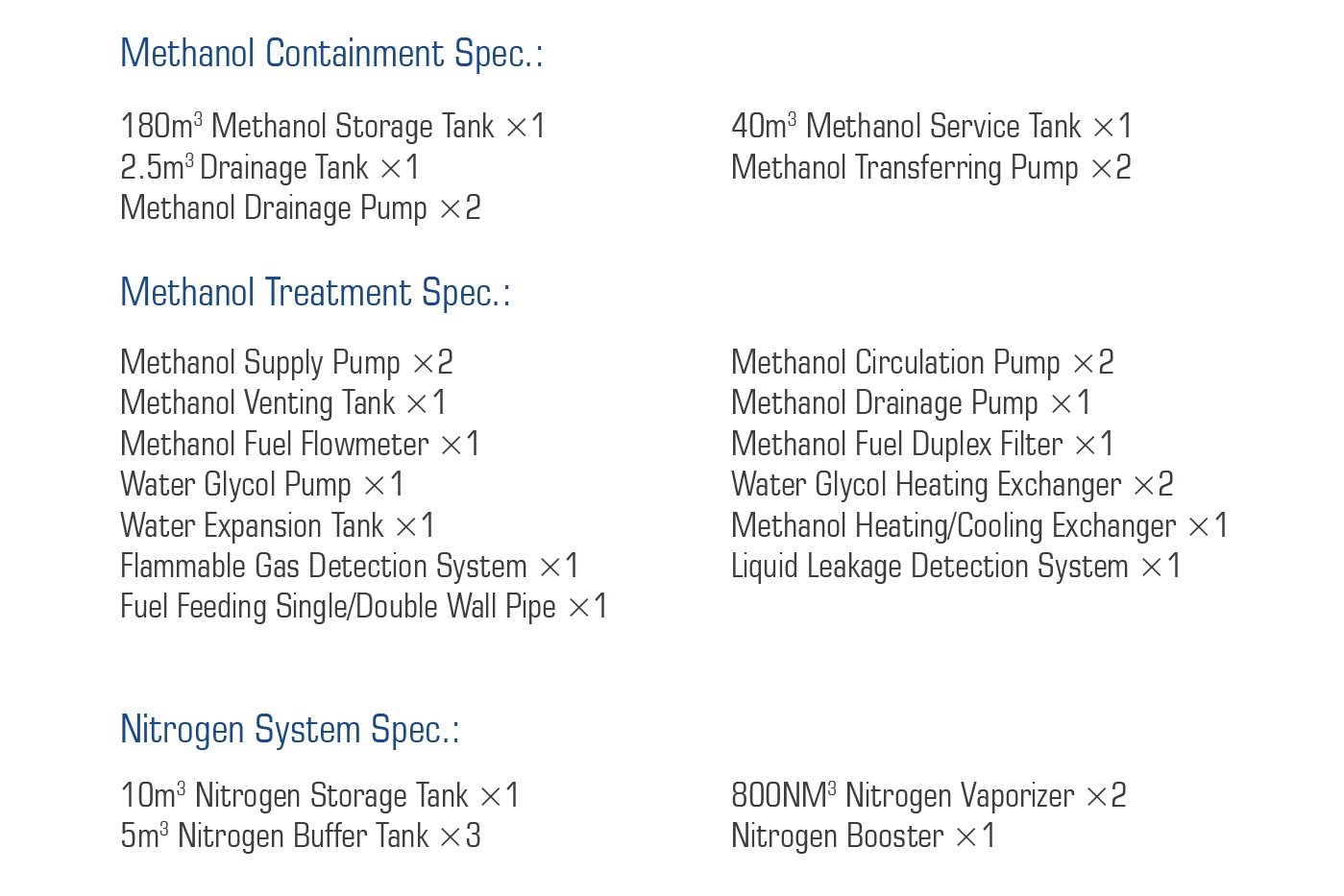

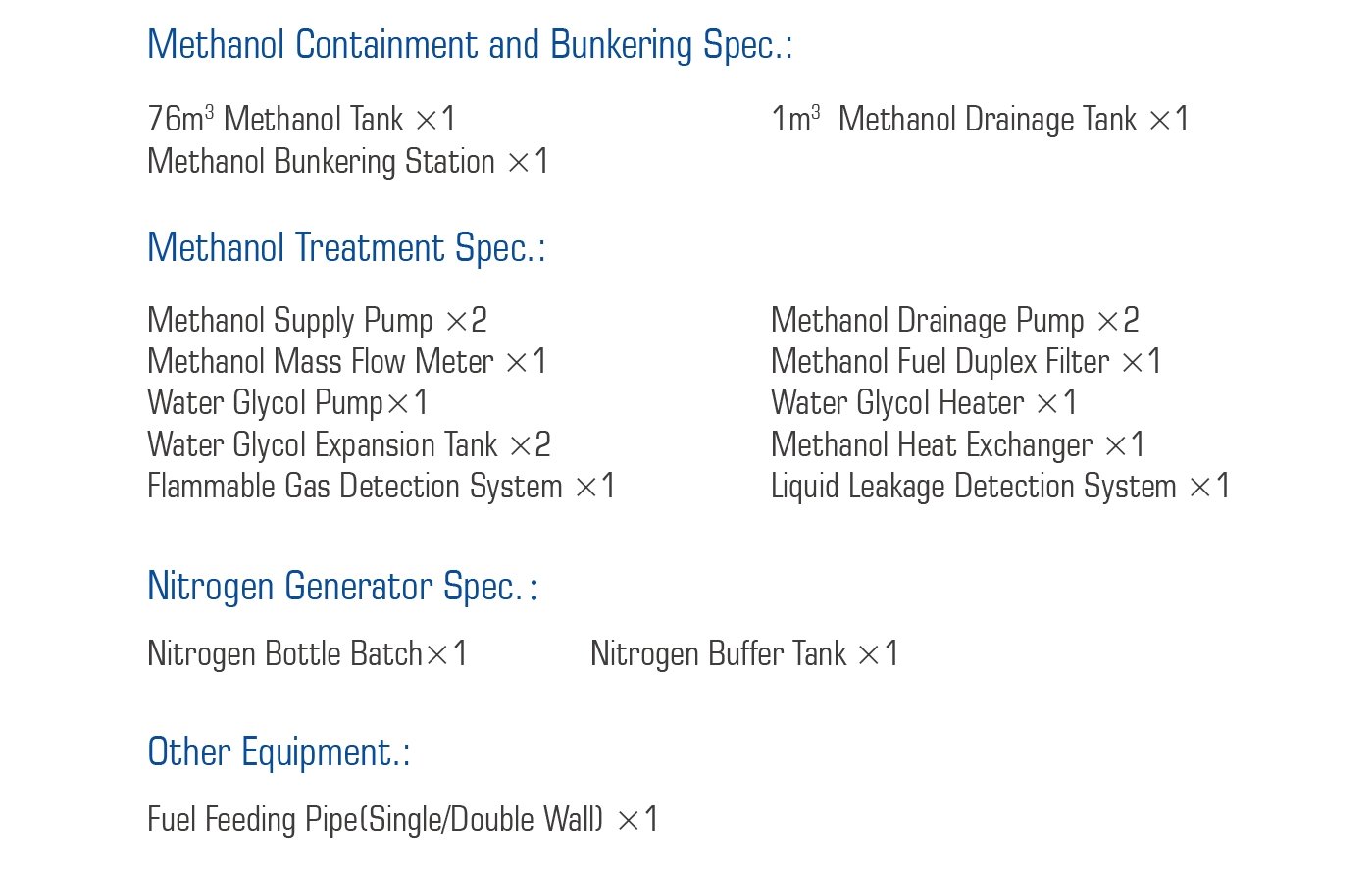

Dalian Marine Diesel Engine Co., Ltd. (DMD) utilizes Headway's one-stop solution for its CSE test platform. This comprehensive system integrates a Methanol Fuel Supply Module, Bunkering and Containment Module, Auxiliary Heat Exchange System, Nitrogen Generator, and Safety & Control System. Notably, Headway independently researched, developed, and manufactured both the solution and its individual modules. This achievement marks the first commercially applied LFSS in China.

General Information

LFSS Model: OG-LFSS-LP-M35-N

Location: Dalian, China

Customer: CSSC Engine Co.,Ltd. (CSE)

Engine: MAN 9G95ME-LGIM, MAN 7G80ME-LGIM,

MAN 7S60ME-LGIM, MAN 6G50ME-LGIM

Main Particulars

This pioneering project marks the world's first bulk carrier exceeding 10,000 DWT to utilize electric propulsion. Headway supplied a turnkey methanol fuel supply system for the vessel.

General Information

LFSS Model: OG-LFSS-LP-M1-N

Location: Hubei, China

Class: CCS

Customer: Guoneng Ocean Shipping Co., Ltd.

Engine: ZICHAI Z8180/SCM

Main Particulars

Headway tailored a methanol fuel supply system for WeiChai's medium-speed engine, specifically designed for R&D, testing, and commissioning of their methanol DF engine. The LFSS surpassed WeiChai's expectations in both functionality and flexibility, garnering positive customer feedback.

General Information

LFSS Model: OG-LFSS-LP-M1

Location: Chongqing, China

Customer: Weichai Heavy Machinery Co., Ltd.

Engine: Medium-Speed Engine Manufactured by WeiChai Heavy Machinery

Main Particulars

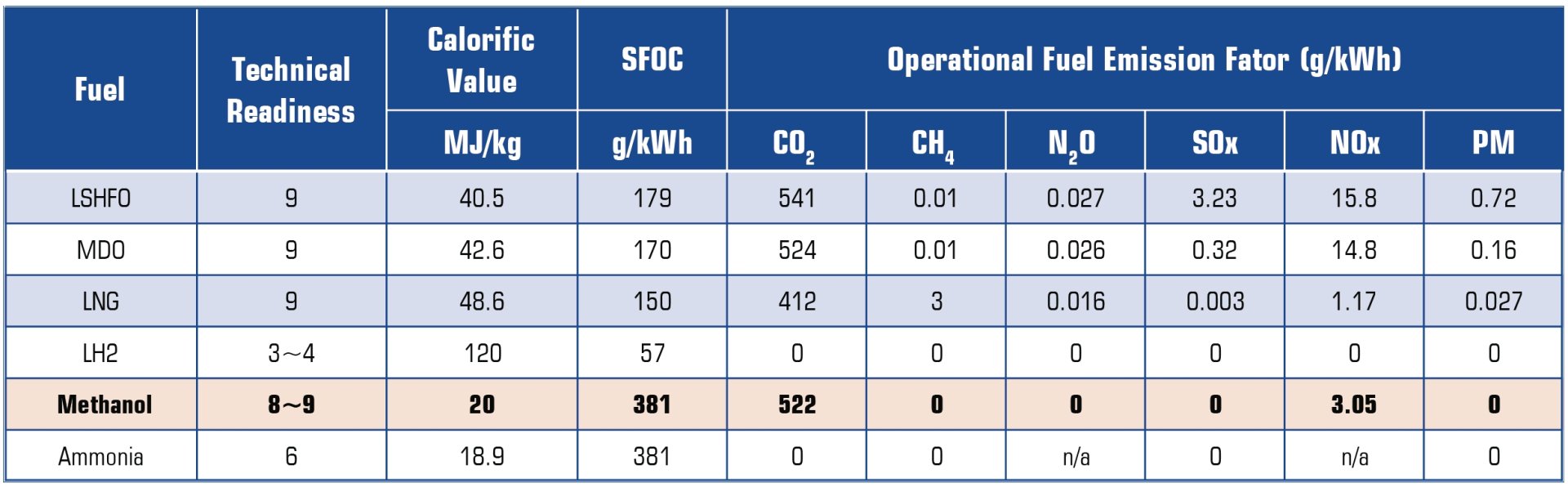

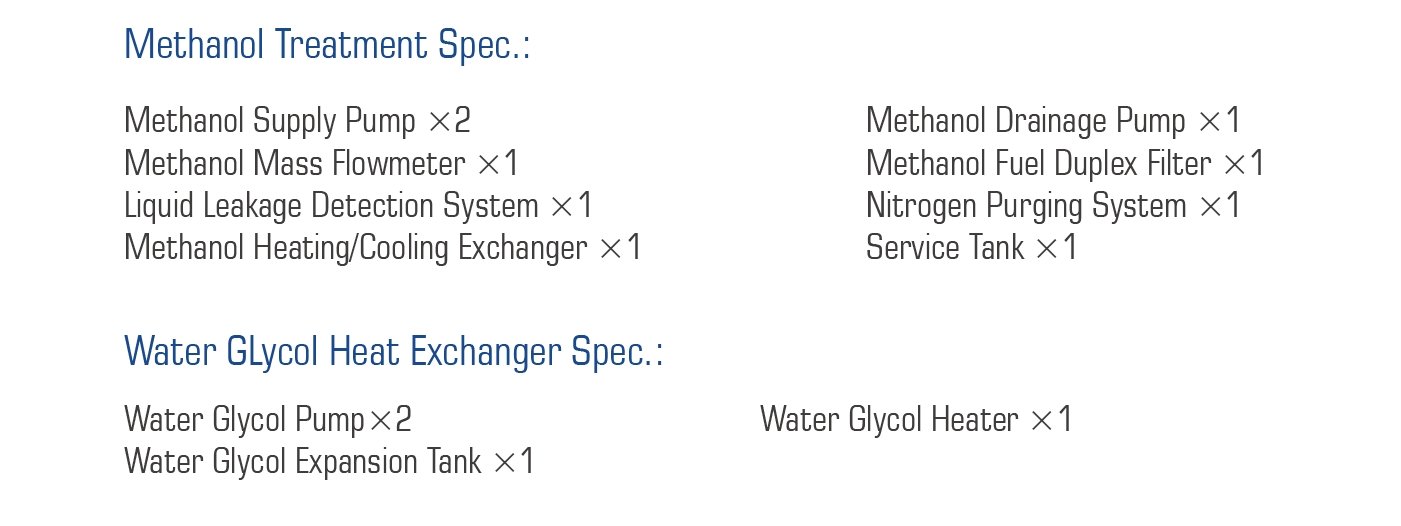

The vessel is the first one in the world that leverages the MAN 21/31 GenSet as its main propulsion system. Headway provided a comprehensive one-stop solution for the vessel, encompassing core modules such as the Bunkering and Transfer System, Methanol Treatment System, Double Wall Pipeline Purging System, and Safety & Control System.

General Information

LFSS Model: OG-LFSS-LP-M1

Location: Singapore

Class: RINA

Customer: Fratelli Cosulich Bunkers (S) Pte Ltd

Engine: MAN E&S 6L21/31DF-M

Main Particulars