OceanGuard FGSS is an independent intellectual property of Headway Technology Group. Joint with the resources of leading research institutes and universities, Headway is providing an advanced solution that is compatible with Medium-Speed/Low-Speed Dual-fuel marine engines, inland river single/dual-fuel engines and generators. With the support of branch companies and 120 service stations across 56 countries and regions, Headway is capable of providing localized, comprehensive, and timely technical service and solution of LNG fuel supply.

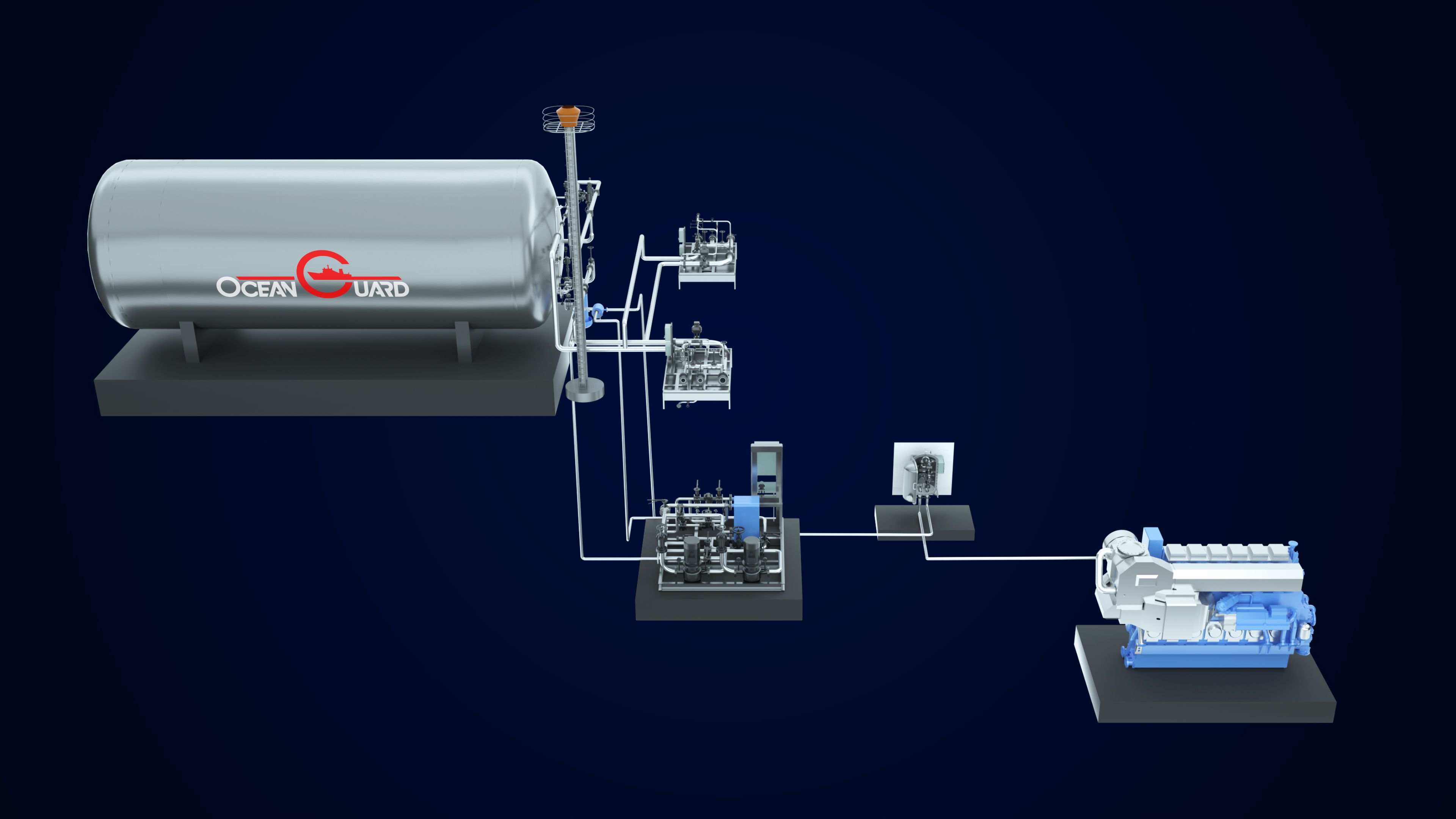

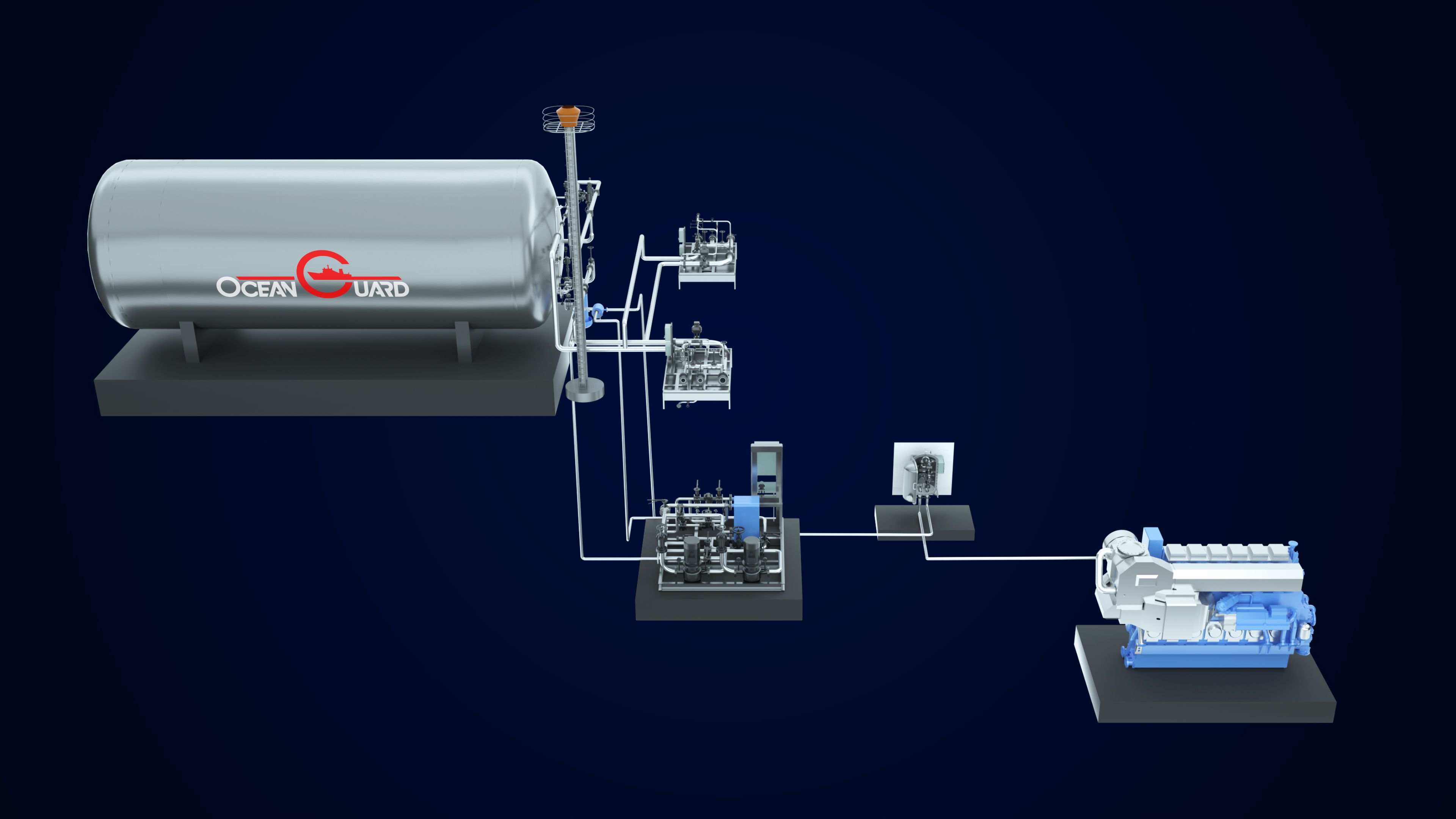

OceanGuard FGSS can fit a land-based bunkering station, bunkering vessel, or tank trailer. During the process, LNG is loaded to a preset volume from the bunker station. When supplying the fuel gas to consumers, LNG enters the pump pool of the submerged pump from the tank through gravity flow and is pumped into the vaporizer. The pressure and volume of resultant natural gas are then regulated by a Gas Valve Unit before being supplied to the consumer. The vaporizer takes Water-Glycol as a media, the water glycol is heated by the heat source onboard the ship and supplied to the exchanger to complete a heat exchange circuit. Under an emergency pressure spike inside the LNG tank, the safety valve will automatically release the pressure to ensure the safety of the personal and equipment.

When supplying LNG to ME-GI engines, LNG is pumped from the low-pressure fuel pump to the high-pressure vaporizer. When reached the preset pressure and temperature, the resultant natural gas enters the buffer tank before supply to the engine through the Gas Valve Unit.

Empowered by the professional R&D and manufacturing team, all critical components of the OceanGuard FGSS are independently researched and manufactured by Headway. With the customized and modular design, OceanGuard FGSS can provide an optimized layout based on the internal space of existing vessels.

Tripartite supported by the experience of design and manufacture of pressure vessels, advanced manufacturing facilities, and strict quality control system, Headway can design and manufacture LNG tanks according to IGF, IGC, and Class regulations on low flash point fuel transport and powered vessels for all types of ships. With CAE Aided Lightweight Design, Headway can make the maximum balance of the lighter tank weight and best thermal insulation while ensuring the best reliability.

The Control Unit is the core of OceanGuard FGSS. Refined from the experience in Ballast Water Management System and Exhaust Gas Cleaning System, OceanGuard FGSS has passed comprehensive bench test according to IMO and Classification Society's regulation. The redundancy and diversity design provides a real-time self-monitoring functionality while ensuring safety, stable and redundancy.

The modular designed Inert Gas Generator applies Hollow Fiber Film Technology to ensure Nitrogen generation with high efficiency, low consumption, and easy maintenance. The generator can meet the inert gas requirement of LNG Tanker, Chemical Tanker, Bunkering Vessel and Offshore Bunkering Station. Moreover, Headway is capable of independent research of Reliquefication Unit, Heat Exchanger, and Double Wall Pipes.

Headway also developed a Smart Fleet Management Platform which can monitor all critical parameters of the FGSS on a real-time basis.

OceanGuard FGSS has obtained the AiP certification issued by DNV, RS, BV, ABS, RINA, and NK. It is also the first in the industry to obtain the Functional Safety Certificate.